Hot Mopped Rolled Roofing

I am not familiar with using silicone over foam board.

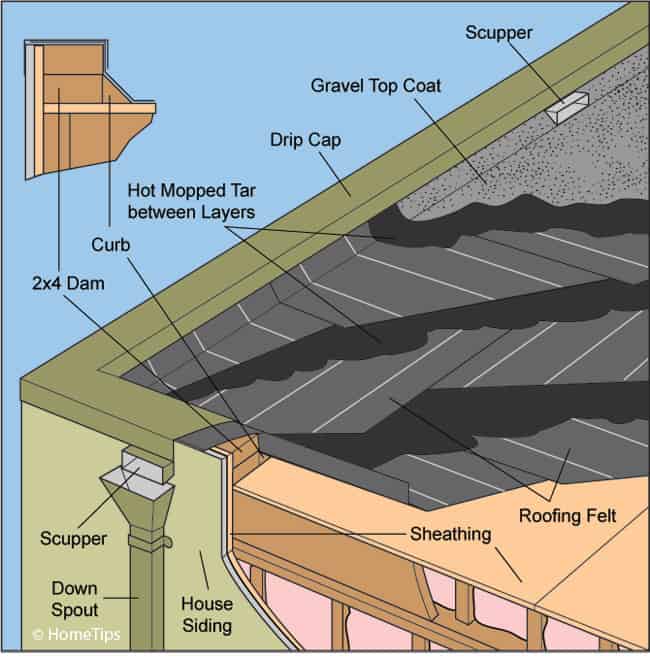

Hot mopped rolled roofing. Hot mop roofing is not a diy job. A leak free bur mandates proper selection of roofing materials. To install hot mop roofing roofers lay a synthetic base layer top it with a felt layer then pour liquid tar on the roof and spread this sealing compound with a mop which gives the process its name. Embed the roll in asphalt applied at the nominal rate of 25 lb per 100 square feet.

Alternately spot mop the deck with. Our roofing installers also pay attention to the flashings and penetrations while carrying out the job. However technology has come to forever replace the need for a hot mop tar roof. To install torch down roofing roofers roll out sheets of a bitumen containing material.

This is definitely a professional only roofing category. On a sloped roof hot mopping begins by embedding a 90lb felt or modified bitumen cap sheet in hot asphalt. Hot mopped roofing information pricing rolled hot mopped roofing a time tested solution for commercial roofs. A built up hot mop roof consists of layers of felt and asphalt over a bed of rosin paper.

This can be accomplished by picking up the roll at each end and at the outside edge turning it over and setting it immediately onto hot mopping asphalt. Silicone roof coatings are used mainly in commercial buildings to restore old hot mop roofs and as a protective coating over spray foam roofing. We take into account the climate and slope before finalizing on the products that ll need to be used. Because of the fumes released by liquefying asphalt hot mopping contributes to smog production.

Hot mopping may not be allowed in every jurisdiction or it may be. Hot mop roofing is a very dirty and somewhat dangerous job it s essentially putting molten asphalt tar over a roof. It protects your base sheet and keeps your roof watertight by acting like a secondary water barrier between the dry in materials and the tiles. People have been trying to come up with a different flat roof roofing product and the first to get a good toehold was a product called torch down roofing.

For hot mop application solidly mop the full width of the sheet to be covered including the lap in roofing asphalt. Silicone roof coatings have an average life span of 10 to 15 years but can usually be recoated at that time. One concern with foam board insulation is shrinkage and expansion putting stress on. A range of lifespans.

Some types of rolled roofing can also be nailed or fastened to the roof to greater facilitate the installation. As they roll the material out they hit it with the flames of a torch melting it and allowing it to. If you ve ever seen a hot mopped roof install you ll be thankful your not the one doing it. Depending on what type of roofing you choose your rolled roof could last between 10 and 20 years with some types lasting longer.

The second step in the re roofing process the hot mop is an essential part of a tile roof system. The material is back nailed to secure. This was a mediocre replacement and as the name implies was installed by using fire and melting. Reflective gravel or a cap sheet limits sun damage and improves the roof s appearance.

Normally the rolls are laid out on the roof and trimmed prior to the adhesive being applied to help make the process easier.